- Home

- Products

- Industrial Shredder

- Single Shaft Shredder

Single Shaft Shredder

The single shaft shredder offers a great solution for recycling various solid wastes, including rubber wastes, plastic wastes, PET bottles, cardboard paper, printed circuit boards, waste wood, plastic buckets, power cables, and more. It is one of our basic models integrating functions of industrial paper shredders, wood shredders, rubber shredders, plastic shredders, cable granulator, etc.

Clients could select the corresponding single shaft shredder models according to the material size and quantity. You should specify the special requests if the industrial shredder is used for extremely hard materials, such as high strength engineering plastics including nylon, ABS and PC.

The single shaft shredder is composed of main shaft, stator knives, loading shell, shell supports, intake system, hydraulic pushing system and electronic control system. Materials are delivered into the shredding chamber by the intake system, and pushed to the blades inside the shredding chamber. After being shredded, squeezed and sheared, the processed materials in small pieces will be discharged through the screening mesh in the single shaft shredding machine.

Features of the Single Shaft Shredder

1. DC53 steel is used for rotor blades, and D2 steel is used for stator blade.

2. Main electronic components for the heavy duty shredder are from Siemens and Schneider.

3. Microcomputer technology can make rotator start, stop and reverse.

4. Automatic reverse sensors are applied to protect the single shaft shredder against over loading and jamming.

5. Split-type bearing block is adopted so the blades can be changed quickly and efficiently.

6. The specifically designed rotor is extremely wear resistant.

7. The running costs and reduce the downtime are remarkably reduced.

8. Our single shaft shredder is able to process a number of kinds of material.

9. All the machinery and electrical devices are protected in accordance with the European CE standard.

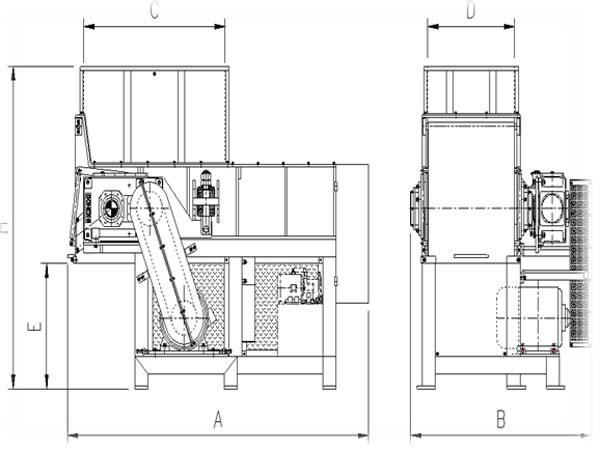

Technical Specifications of Single Shaft Shredders| Model Item |

|||||||||||

| A(mm) | 1780 | 1780 | 2455 | 2455 | 2825 | 2825 | 2825 | 2825 | 3135 | 3255 | 3255 |

| B(mm) | 1190 | 1350 | 1478 | 1678 | 1747 | 2004 | 2564 | 2964 | 2968 | 4415 | 4615 |

| C(mm) | 857 | 857 | 1200 | 1200 | 1410 | 1410 | 1410 | 1410 | 1650 | 1450 | 1560 |

| D(mm) | 502 | 602 | 600 | 800 | 800 | 1000 | 1200 | 1500 | 1500 | 2000 | 2500 |

| E(mm) | 546 | 546 | 500 | 500 | 500 | 500 | 500 | 560 | 600 | 950 | 950 |

| H(mm) | 1754 | 1754 | 1700 | 1700 | 1875 | 1875 | 1875 | 1935 | 2105 | 2720 | 2720 |

| Cylinder Stroke(mm) | 500 | 500 | 750 | 750 | 900 | 900 | 900 | 900 | 950 | 950 | 1000 |

| Rotor Diameter(mm) | φ224.7 | φ224.7 | φ300 | φ300 | φ390.3 | φ390.3 | φ390.3 | φ390.3 | φ453.9 | φ464.8 | φ454 |

| Main Shaft Speed (r/min) | 83 | 83 | 83 | 83 | 74 | 74 | 74 | 74 | 74 | 75 | 75 |

| Screen Mesh(mm) | φ25 | φ25 | φ40 | φ40 | φ40 | φ40 | φ40 | φ40 | φ40 | φ40 | φ40 |

| Rotor Blade Quantity / Flat Blade Quantity (PCS) | 24+4 | 28+4 | 30+4 | 42+4 | 42+4 | 54+4 | 66+4 | 90+4 | 90+4 | 114+4 | 144+4 |

| Stator Blade Quantity (PCS) | 2+2 | 2+2 | 2 | 2 | 2 | 2 | 2 | 3 | 3 | 4 | 5 |

| Main Motor Power(KW) | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 | 75 | 90 | 75+75 | 90+90 |

| Hydraulic Motor Power(KW) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 5.5 | 5.5 | 5.5 | 7.5 | 7.5 |

| Weight(KG) | 1300 | 1400 | 1550 | 1950 | 3500 | 4000 | 5000 | 6200 | 7800 | 10000 | 12000 |

3E RECYCLING design and manufacture various shredders and recycling machines, with custom recycling lines and solutions for processing plastic film, PET bottles, rubber tire, scrap metal, municipal solid waste, medical, chemical and industrial waste, etc.

GUANGZHOU 3E RECYCLING CO., LTD.

Add.: No. 98, Taian Road, Shiji Town, Panyu District, Guangzhou

Tel.: +86-20-84729983

Fax: +86-20-84557969