3E Recycling's waste PET bottle shredding washing recycling solution is specially responsible for the shredding, cleaning, separating of bottle cap and label, drying, and packaging for waste PET bottles. It could be used to recycle all kinds of PET bottles.

Waste PET bottle shredding washing recycling line integrates granulator or shredder, inclined screw feeder, friction washer, zigzag classifier, centrifugal dewatering machine, and many others. The line is highly automatic, featuring low energy consumption, high working efficiency, and good cleaning effect. Meanwhile, with the waste PET bottle shredding washing recycling line, waste PET bottles could be converted to PET materials, enabling further usage.

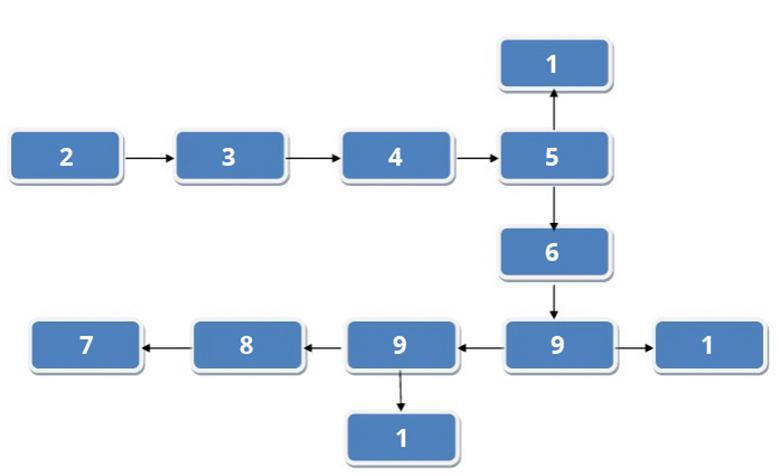

1. Label collector; 2. Zig zag classifier; 3. Shredder; 4. Friction washer; 5. Hot washing tank; 6. Centrifugal dewatering machine; 7. Hot air dryer; draught fan; 8. Sink float tank; 9. Sink float tank

Waste PET Bottle Shredding Washing Recycling Line Introduction| Output | 300-2000 kg/h |

| Application | Enables the treatment of all kinds of waste PET bottles, including purified water bottle, soft drink bottle, oil bottle, PET milk bottle, PP bottle and etc. |

| Feature |  Waste PET bottle shredding washing recycling line integrates granulator or shredder, inclined screw feeder, friction washer, zigzag classifier, centrifugal dewatering machine, and many others. The line is highly automatic, featuring low energy consumption, high working efficiency, and good cleaning effect. Meanwhile, with the waste PET bottle shredding washing recycling line, waste PET bottles could be converted to PET materials, enabling the production of high quality products. Meanwhile, these treated materials could also be used for brushing, pelleting and bottle blowing. Waste PET bottle shredding washing recycling line integrates granulator or shredder, inclined screw feeder, friction washer, zigzag classifier, centrifugal dewatering machine, and many others. The line is highly automatic, featuring low energy consumption, high working efficiency, and good cleaning effect. Meanwhile, with the waste PET bottle shredding washing recycling line, waste PET bottles could be converted to PET materials, enabling the production of high quality products. Meanwhile, these treated materials could also be used for brushing, pelleting and bottle blowing. |

| After-sales service | Sophisticated installation team and commissioning team offer installation instruction and training service for our customers. |

2. Friction washer

Friction washer is mainly used to clean the impurities on shredded PE / TPP films and PE/ PP/PET sheets, like dusts and etc. The friction washer, made of stainless steel material, enjoys excellent corrosion resistance. Meanwhile, due to the introduction of corrosion resistant material, its blades could be used for a long period of time.

Rotary screen: Rotary screen is mainly responsible for the prior stage treatment for waste plastic bottles, which

3. Washing

Sink float tank: Sink float tank is designed to separate impurities and useful material according to different densities.

4. Dewatering

Centrifugal dewatering machine: Mainly applied to dry waste plastic (granule). The machine enjoys excellent drying effect, and dried materials only contain 2.5% or even lower water. Its bearing is designed as water resistant one, so it could be operated stably in a long period of time. In addition, places which may have direct contact with water are all made of 304 stainless steel.

1. PET bottle cleaning line for a República Dominican customer

It was put into production in 2011 with an hourly output of 500kg.

2. PET bottle cleaning line for a República del Ecuador customer

The cleaning line was put into production in 2012, and its hourly output is 300kg/h.

3. PET bottle cleaning line for a South African customer

Put into production in 2015, the line owns an output of 500kg/h.

4. Waste PET bottle shredding washing line for a Hong Kong user

The waste PET bottle shredding washing line was put into production in 2015. Its hourly output is 2000kg.