Scrap Metal Recycling Plant / Scrap Car Recycling Line

Primarily designed for scrap car recycling purpose, the scrap metal recycling plant adopts a specially designed heavy duty metal shredder for the preliminary crushing, and a horizontal heavy-duty crusher for further process. After that, a blower and special structures are used in the scrap car recycling line for removing the dust, and a powerful magnetic separator is used for separating the metal (mainly iron). The gear box of the scrap metal recycling plant is replaced by a hydraulic motor to increase the torque, making the working process more stable. This also results in less worn mechanical components in the waste recycling plant.

Our company has acquired 8 invention patents and 23 utility model patents in the last ten years, providing technical foundation for the scrap metal recycling equipment.

Invention patents: processing techniques and equipment before recycling scrap car shells ZL201010624847.9

Utility model patents: processing equipment before recycling scrap car shells ZL201020701426.7

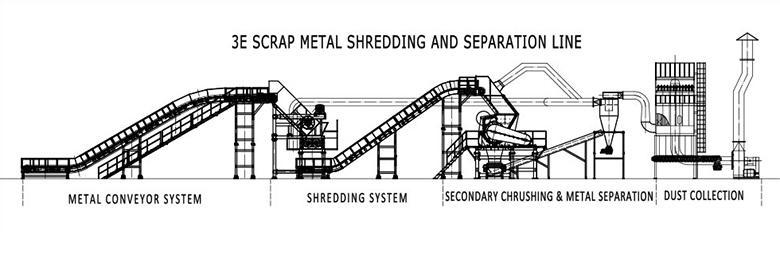

Production Layout

Features of the Scrap Metal Recycling Plant

Production Capacity: 5-40 set/hour

Production Control: Siemens PLC controller and real-time dynamic monitoring

Low energy consumption, large production capacity, low maintaining cost

The blades of the metal recycling machine are detachable, so it is convenient to demount, repair and maintain them.

3E RECYCLING design and manufacture various shredders and recycling machines, with custom recycling lines and solutions for processing plastic film, PET bottles, rubber tire, scrap metal, municipal solid waste, medical, chemical and industrial waste, etc.

GUANGZHOU 3E RECYCLING CO., LTD.

Add.: No. 98, Taian Road, Shiji Town, Panyu District, Guangzhou

Tel.: +86-20-84729983

Fax: +86-20-84557969