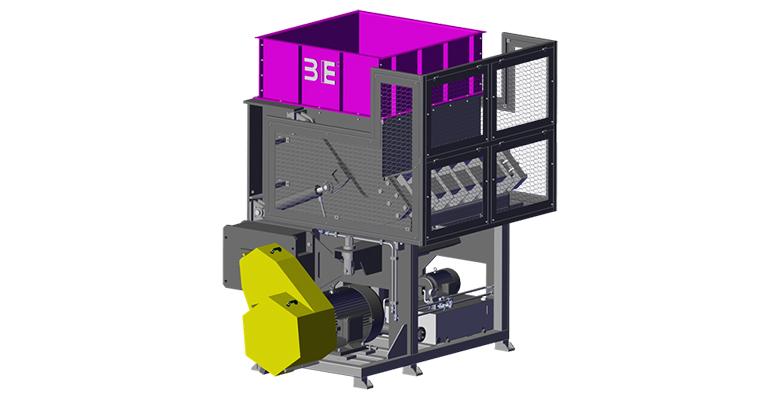

The waste disposal line is specially designed for medical waste's shredding. Its cutting tool is made of imported high-quality steel, which is highly corrosion resistant, and could be used to shredding all kinds of medical wastes, like plastic wastes, medical clothing, used medical gauze, clinical waste, infectious waste, used syringes and etc. Medical waste disposal line's shredding unit and driving unit are multi-layer sealed, so the splashing during shredding period could be well prevented. Shredded wastes enjoy universal size, which is 45mm or smaller than 45mm. Meanwhile, more than 96% of them could be recycled, which well meets the national standards of shredding, burning and disposal. 3E Recycling's medical waste disposal line is designed with low speed, high torque, low noise and utilizes Siemens's programming control system, allowing automatic controlling towards starting, stop, inversion and others.

Wide application:

Medical waste disposal line could be widely used to dispose plastic wastes, medical clothing, used medical gauze, clinical waste, infectious waste, used syringes and etc.

Features:

1. Shredding unit and driving unit are designed with multi-layer sealing, so the safe operation could be ensured.

2. Blade used in our disposal line is made of imported high-quality steel, which is highly resistant to corrosion and abrasion.

3. Multi-layer sealed shredding unit and driving unit enables zero leakage of leachates.

4. Double-wall cabinet is outfitted with a corrosion resistant layer, which could be easily changed.

Our support

1. Professional consultation:

According to different materials supplied by customers, we offer customized medical waste disposal solutions to them.

2. Installation and commissioning service:

Sophisticated installation and commissioning team is always available to provide customer in-time installation instruction and training support.

3. Hotmail:

In order to in-time handling towards emergencies and minimize your cost due to equipment problem, you could get in touch with our engineer at any time.

4. Abundant parts:

In order to minimize customer's cost on parts and offer prompt delivery, 3E Recycling is outfitted with a large amount of parts, so we could provide prompt part offering for our customers.

5. Professional training:

To make sure your technicians are in well grasped towards our equipment's performance, operation and maintenance methods, 3E Recycling offers both on-site installation instruction and all kinds of operation philosophy training to them. Thus, a prompt and comprehensive grasping towards operation technologies could be realized.

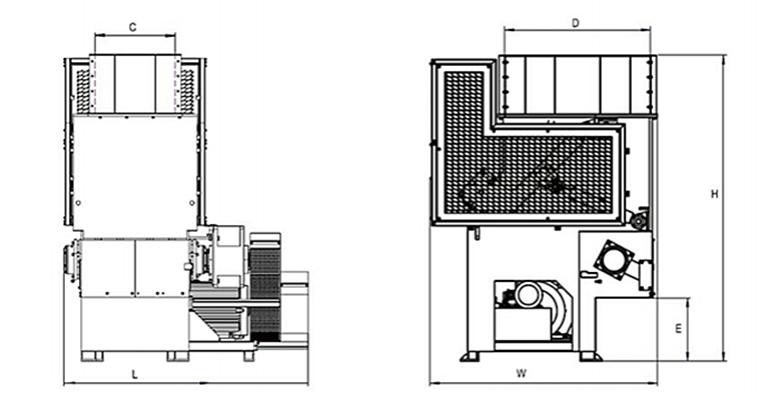

| Model | MW4080 | MW40150 |

| Overall dimension L/W/H(mm) | 2450×2280×3085 | 3150×2280×3150 |

| Shredding unit size C/D(mm) | 800×1460 | 1500×1460 |

| Discharging port height H(mm) | 640 | 640 |

| Cutting tool's inversion diameter (mm) | φ400 | φ400 |

| Opening size (mm) | φ40 - φ60 | φ40 - φ60 |

| Rotor blade quantity (pcs) | 42+4 | 90+4 |

| Stator blade quantity (pcs) | 2 | 3 |

| Main motor size (kw) | 37 | 75 |

| Hydraulic pressure power (kw) | 7.5 | 7.5 |

| Motor's protective class | IP44 | IP44 |

| Overall weight (kg) | 6750 | 8350 |

Medical waste disposal and recycling line for a Chongqing customer

Medical waste disposal and recycling line for a Chongqing customer Medical waste disposal and recycling line for a Guizhou customer

Medical waste disposal and recycling line for a Guizhou customer Medical waste disposal and recycling line for our Inner Mongolia customer

Medical waste disposal and recycling line for our Inner Mongolia customer