3E Recycling's fridge recycling line is mainly designed to crush and separate the casings of fridge and freezer when their Freon and compressor are removed. The fridge recycling line is composed of shredder, granulator, and recycling machine, featuring high automation, efficient treatment, low working cost and no secondary pollution.

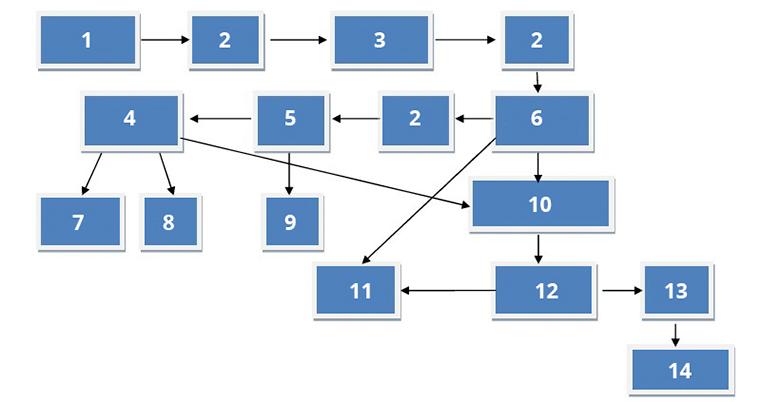

1. Rotary conveyor; 2. Belt conveyor; 3. Double-shaft shredder; 4. Eddy current separator; 5. Magnetic separator; 6. Vertical granulator; 7. Non-ferrous metals; 8. Plastic; 9. Iron; 10. High pressure fan with hammer; 11. Dust removal system; 12. Cyclone collector; 13. Rotary valve; 14. Foam recycling compactor

Fridge recycling line allows the separation of all kinds of impurities, like, iron scraps, plastic scraps and etc. from fridges.

-

Iron scraps

Iron scraps -

Nonferrous scraps

Nonferrous scraps -

Plastic scraps

Plastic scraps -

Foam scraps

Foam scraps

Features:

1. Imported wearable steel is utilized to our fridge recycling line, so it enables more than eighty thousand pieces of fridges' recycling.

2. The fridge recycling line's output could either be 50~60 pieces per hour or 80~100 pieces per hour.

3. Sorting effect: Iron scrap's recycling rate is higher than 98%; plastic scrap's recycling rate is higher than 98%; and our foam scrap's recycling rate is higher than 95%.

4. Iron scrap features a volume density of 0.7T/M3 or even higher one. Scraps of different materials share similar sizes, so as ensure a good separation effect.

5. Foam compression ratio is 1:7.

6. Especially suitable for large fridges and freezers.

7. The recycling line owns a unique design and it reaped a national patent with its patent number of ZL2011 2 0325659.6.

8. Materials' separation, dust removal and air discharging are carried out independently. Meanwhile, due to the installation of separate ventilation system, both environmental friendliness and safe production could be guaranteed.

9. If required, our fridge recycling line could be designed with a remote controlling system, which enables real-time monitoring towards its processing.

Double shaft shredder utilized in our fridge recycling line is one of the heavy duty shredders, which introduces a hydraulic driving system for use in rough shredding towards waste fridge casings. After that, these shredded ones may be recycled directly or undergo fine treatment in accordance with customer requirement. Double shaft shredder features low speed, large torque, low noise and many other advantages. Besides, due to its introduction of Siemens programming system, automatic controlling towards its activation, stop, inversion and inversion of control during overloading period are all satisfied.

Hammermill shredder

Some of the metal scraps underwent rough shredding requires further treatment so as to meet customers requirement towards their sizes. Hammermill shredder is cost effective, practical, easy operated, durable and easy maintained. Besides, it also allows easier discharging towards impurity discharging. Bulk density of our finished iron scraps is higher than 1t/m3.

Magnetic separator

With the help of magnetic force, metals with iron content could be effectively separated.

Eddy current separator

Eddy current separator is mainly composed of two parts, one of the main part – separation system, and the other is control cabinet. The major part could be divided into separation assembly, driving motor, frame, casing and etc. Eddy current separator is mainly designed to separate all kinds of non-ferrous metals, including copper, aluminum and etc. from industrial solid wastes, like, electronic waste, waste plastic doors and windows, waste cars and so on.

Central controlling system

Our central control system utilizes Siemens' PLC (programmable logic controller), allowing effective real-time monitoring and effective controlling towards the whole recycling line. It is one of the real-time controlling system, enabling easy operation.

Foam recycling compressor

Foam recycling compressor is designed for foam's further crushing, enabling the gas's evolution from foam pores and easier packing and delivering.

1. Fridge recycling line

It was put into production in 2011 with an hourly output of 30 pieces per hour.

2. Fridge recycling line for a Guangdong customer

It was put into production in 2013, and its hourly output is 30 pieces.

3. Fridge recycling line for Jiangxi customer

The fridge recycling line was put into production in 2014, and it could recycle 30 pieces of fridges in a single hour.

4. Fridge recycling line for Hebei customer

Fridge recycling line for Hebei customer was put into production in 2016, and its output is 40 pieces per hour.

5.Fridge recycling line for Helongjiang customer The fridge recycling line designed for our Helongjiang customer was put into production in 2017 with an hourly output of 60 pieces.

6. Fridge recycling line for Shandong customer

The recycling line was put into production in 2017. Its hourly output is 60 pieces of fridges.

7. Fridge recycling line for Guangdong Province

The recycling line was put into production in 2017 with an hourly output of 100 pieces.