- Home

- Products

- Industrial Shredder

- Film Shredder, SWTF Series

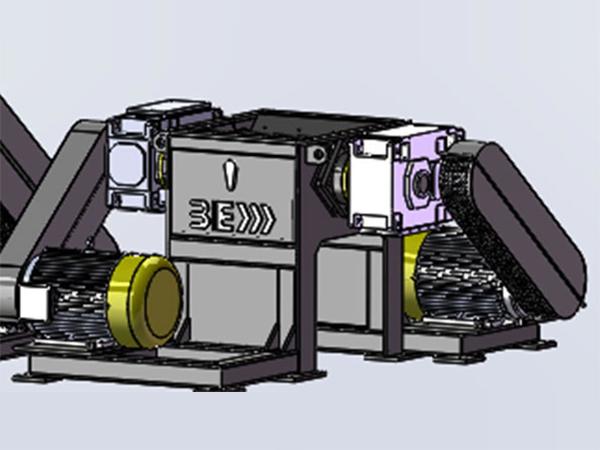

Film Shredder, SWTF Series

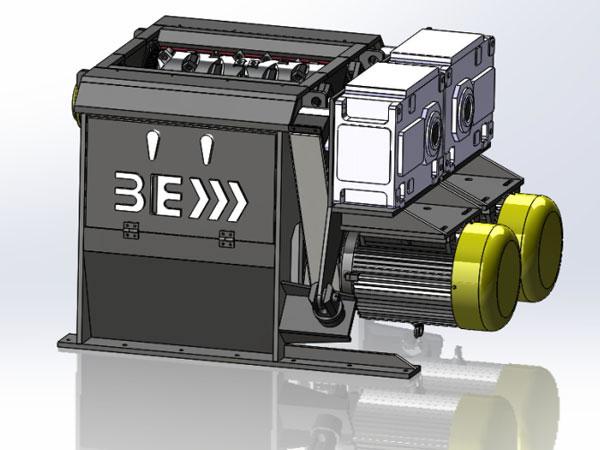

SWTF series film shredder adopts double film shafts design that rotates a medium speed, it features of low noise and high efficient without pusher.

This bag shredder is especially suitable for recycling the medium hardness and soft material, for example film, woven bag, jumbo bag, paper and so on. Aiming at different material, it could use different shaft.

Adopts SIENMENS microcomputer control system with functions of automatic start, automatic stop, and automatic reverse sensors to protect the shredder against over loading and jamming.

Applications

· Film

· Woven bags/ Big bags/ Tons bags

· Wood

· Paper

Key Features of Film Shredder

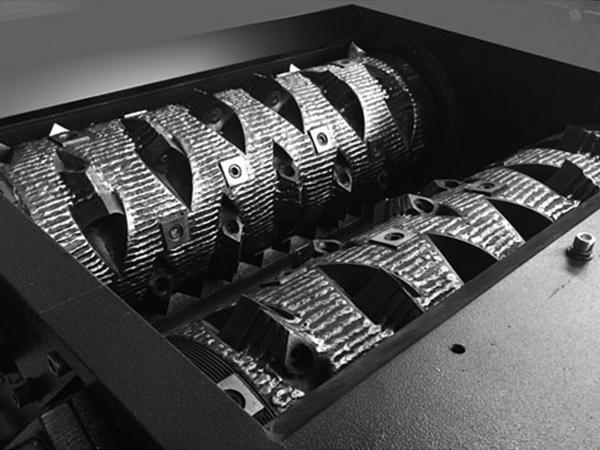

1. Double Shaft Design: Particularly design for soft material. Greatly improve the efficiency.

Without Pusher: It is more efficient because the material could be fed directly.

2. Shock Absorber: Absorbs vibration caused by the shredding operation. Makes sure the shredding process to be steady.

3. Gear Box: Hardened teeth on the reducer.

4. Bearing Seat: Protective bearing is covered to avoid foreign contamination entering the bearing housing.

5. Screen: Z type screen is mainly used for film material that can avoid jamming, and the output is more smoothly. Different screen size meets different customers requirement.

6. PLC Control System: Safety devices of our paper shredder are complied with CE standard.

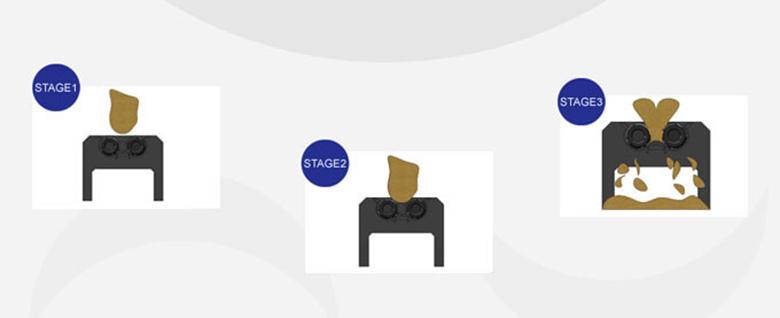

STAGE-1 Materials are fed into the rotor which has set the appropriate rotary speed.

STAGE-2 Materials are grabbed inside the blades of film shredder.

STAGE-3 Continuous shredding can maximize the production capacity.

| Model | |

| Item | |

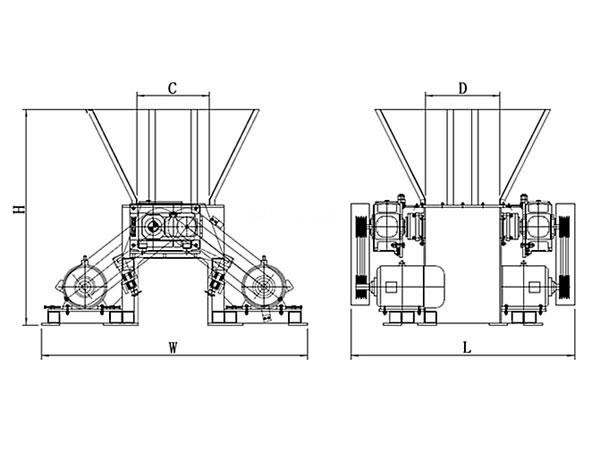

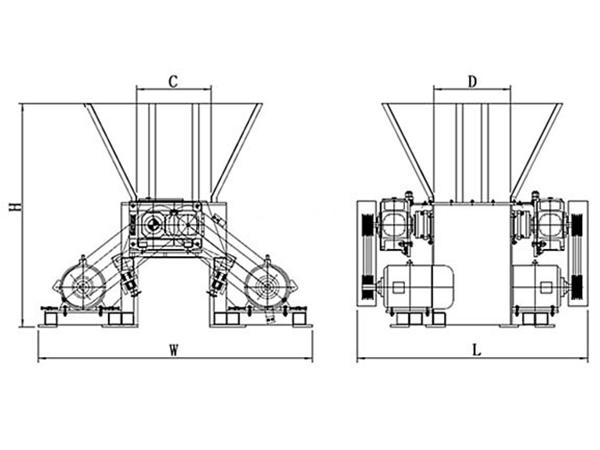

| Dimension L/W/H (mm) | 1834×1561×1735 |

| Cutting Chamber C/D (mm) | 800×576 |

| Height of Discharge Port E (mm) | 535 |

| Rotor Diameter (mm) | φ313 |

| Main Shaft Speed(r/min) | 74 |

| Screen Mesh (mm) | Z 30 |

| Rotor-knives (PCS) | (26+28)×2 |

| Stator-knives (PCS) | 4 |

| Main Motor Power (KW) | 30+30 |

| Weight (KG) | 4400 |

| Model | |||||

| Item | |||||

| Dimension L/W/H (mm) | 2146×1805×1754 | 3470×2601×2275 | 3660×3710×2275 | 3860×3710×2275 | 3710×3860×2435 |

| Cutting Chamber C/D (mm) | 600×450 | 1000×750 | 1200×750 | 1500×750 | 830×1500 |

| Height of Discharge Port E (mm) | 500 | 900 | 900 | 900 | 900 |

| Rotor Diameter (mm) | Φ232.5 | φ400 | φ400 | φ400 | Φ480 |

| Main Shaft Speed (r/min) | 82 | 74 | 74 | 74 | 74 |

| Screen Mesh (mm) | Z 25 | Z 30 | Z 30 | Z 30 | Z 30 |

| Rotor-knives (PCS) | (20+11)×2 | (51+36) ×2 | (60+42) ×2 | (78+54) ×2 | 78×2+54×2 |

| Stator-knives (PCS) | 4 | 4 | 4 | 6 | 6 |

| Main Motor Power (KW) | 18.5+18.5 | 45+45 | 55+55 | 75+75 | 90+90 |

| Weight (KG) | 1800 | 4880 | 5500 | 6500 | 7500 |

3E RECYCLING design and manufacture various shredders and recycling machines, with custom recycling lines and solutions for processing plastic film, PET bottles, rubber tire, scrap metal, municipal solid waste, medical, chemical and industrial waste, etc.

GUANGZHOU 3E RECYCLING CO., LTD.

Add.: No. 98, Taian Road, Shiji Town, Panyu District, Guangzhou

Tel.: +86-20-84729983

Fax: +86-20-84557969