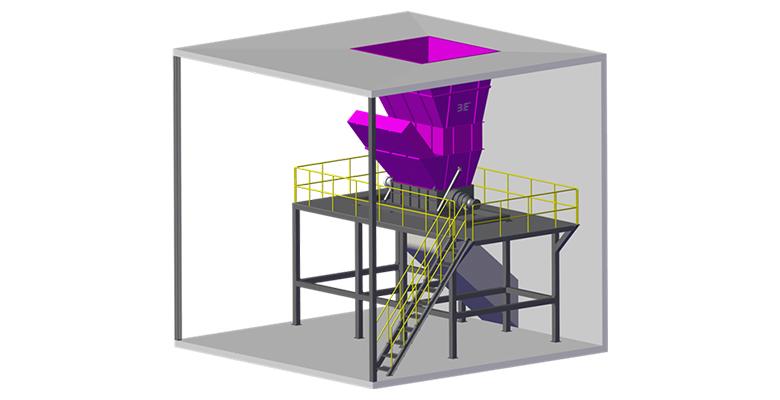

The industrial hazardous waste disposal solution developed by 3E Group is suitable for shredding of hazardous waste, industrial waste, chemical waste, paint bucket, battery, oil filter and some other industrial wastes. The crushing cavity and the power unit adopt multiple sealing device so it has good sealing performance and corrosion resistance. The machine shell can adopt stainless steel according to the requirements. The blades is made of high intensity alloy steel which features good abrasive resistance and relatively high intensity, greatly improving the service life. The design of movable machine enables easy maintenance, uniform material discharging and controllable product size, thus, it can satisfy the shredding requirements of different hazardous wastes. There are also professional and special designs in the following aspects: corrosion resistance, leakage proof, explosion resistance etc. The complete machine is equipped with fire-fighting system of nitrogen and carbon dioxide and safety door, ensuring the good safety and sealing performance during the process of material feeding to shredding.

The industrial hazardous waste disposal solution has wide applications: it can be widely used in shredding of hazardous waste, industrial waste, chemical waste, paint bucket, battery, oil filter and some other industrial wastes.

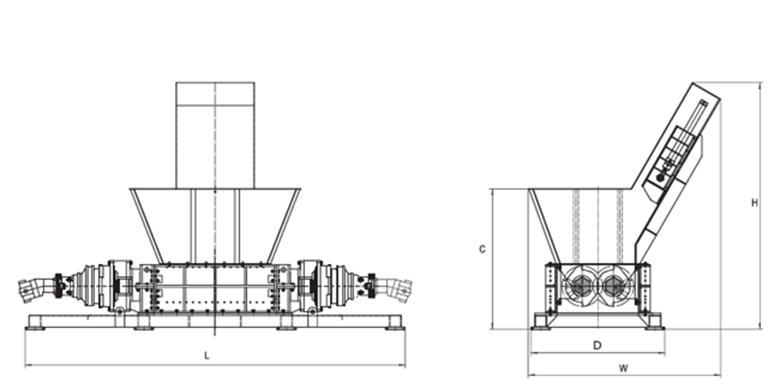

| Type | HW408 | HW410 | HW412 | HW510 |

| Outline dimension L/W/H(mm) | 3685×2030×2917 | 3885×2030×2910 | 4085×2030×2910 | 4554×2600×3160 |

| Crushing cavity dimension C/D(mm) | 800×730 | 1000×730 | 1200×730 | 1000×950 |

| Turning diameter of the blade (mm) | φ430 | φ430 | φ430 | φ510 |

| Blade number (pcs) | 20 | 25 | 30 | 20 |

| Blade thickness (mm) | 40 | 40 | 40 | 50 |

| Main machine power (kw) | 45 | 60 | 60 | 90 |

| Machine weight (kg) | 3100 | 3600 | 4000 | 6000 |

| Type | HW513 | HW516 | HW613 | HW618 |

| Outline dimension L/W/H(mm) | 4854×2600×3169 | 5154×2600×3160 | 5250×2850×3460 | 5750×2850×3460 |

| Crushing cavity dimension C/D(mm) | 1300×950 | 1600×950 | 1300×1200 | 1800×1200 |

| Turning diameter of the blade (mm) | φ510 | φ510 | φ650 | φ650 |

| Blade number (pcs) | 26 | 32 | 26 | 36 |

| Blade thickness (mm) | 50 | 50 | 50 | 50 |

| Main machine power (kw) | 110 | 110 | 160 | 160 |

| Machine weight (kg) | 7500 | 8200 | 11500 | 12600 |

Features:

The industrial hazardous waste disposal solution has the following features:

1. The blades are made of imported alloy steel which features high intensity and good abrasive resistance.

2. The crushing cavity and power unit adopts multiple sealing device so that it is highly corrosion resistant and abrasive resistant.

3. The complete machine is equipped with fire-fighting system of nitrogen and carbon dioxide so it is safe and reliable.

After-sales service of 3E Group:

1. We have professional counselor who can provide specific solutions according to the material to be treated of our customers.

2. 3E Group can provide installation and debugging services: we have experienced installation and debugging technician teams who can provide our customers with rapid installation guide and training supporting.

3. There is a service hotline: in order to support the production factory, you can contact our service engineers immediately 24/7 for emergency. This can minimize the loss caused by shutting down of the machine.

4. The sufficient inventory of parts: in order to reduce the cost of part inventory of our customers and provide better and faster service, we can rapidly provide you with parts with general specifications.

5. We provide professional training: to ensure that the technicians from our customers' company can master the machine performance, operation and maintenance process, we can provide various professional tutorial class in our factory besides normal on-site technical training. So the users of our product can master the technology more rapidly and more all sidedly.

Jiangsu industrial waste shredder

Jiangsu industrial waste shredder Zhejiang industrial hazardous waste disposal solution

Zhejiang industrial hazardous waste disposal solution Jiangsu hazardous waste disposal solution

Jiangsu hazardous waste disposal solution