- Home

- Manufacturing Capability

3E Recycling offers many kinds of machines, including industrial shredder, granulator, and recycling lines for use in waste plastic, waste tire, electric cables and wires, waste domestic appliances, waste circuit board, non-medical waste, hazardous waste and many others in recycling industry. Besides standard products, one-stop service for technical support is also available in 3E Recycling.

3E Group integrates research and development, design, manufacturing and marketing of environmental protection and waste recycling machines. Its main enterprise – 3E Recycling, firstly started in 2003, and since then, it has been dedicated to technical innovation, so as to reap many intellectual properties and state-of-art techniques. Now, 3E Recycling has become a modern enterprise focusing itself on the manufacturing of shredder and recycling lines.

With fifteen years development and expansion, 3E Recycling has grown its capital into 50 million Yuan, and its building area into more than 30 thousand square meters. Now, 3E Recycling has built its own technical support center and has equipped with all kinds of processing machines and testing machines. Meanwhile, we also gained two hundred plus precious staffs, with three dozen of engineers responsible for technical research and development.

3E Recycling owns a comprehensive series of product portfolio, including vertical granulator, single-shaft shredder, double-shaft shredder, four-shaft shredder, plastic recycling line, scrap car recycling line, tyre recycling plant, cable recycling plant, aluminum recycling plant, domestic appliance recycling line, municipal solid waste disposal and recycling line, and etc. In addition, custom recycling line is also available in 3E Recycling.

Each manufacturing process is responsible in charge of matured personnel, and after manufacturing, a comprehensive series of strict tests will be carried out towards our shredder and recycling line.

Introduction towards first workshop:

3E Group owns three manufacturing bases, occupying an overall area of more than 30,000 square meters. They are equipped with modern technical support center and all kinds of processing machines and testing equipment. Staffed with more than two hundred personnel, 3E Recycling has earned forty utility patents, four invention patents and four design patents. In addition, many approvals from authorities and public organizations are all reaped, like, CE Certificate, ISO9001 Quality Management System Certificate, Safe Production License, and provincial famous trademark.

Second workshop

3E Group is outfitted with several fine machining centers. 3E Recycling's manufacturing is in strict accordance with 6S Workplace Organization requirements, design requirements, and industrial norms, together with many years' equipment manufacturing experience, our finished products always enjoy a stable, efficient, and safe operation.

Component introduction:

3E Recycling owns both standard and optional components. Standard components also named as the auxiliary ones, as for their standards, please refer to the prodyuct details.

Optional components

Optional component instruction:

Different from standard components, optional components are not for free, and they owns varied kinds. Meanwhile, different products own different optional components as well. Please refer to the product details or contact our sales manager before you purchase an optional one.

Feature

Best-in-class CNC plasma cutters and CNC flame cutting machines are all utilized to cut our raw mat.

Feature

With sophisticated personnel in monitoring, all kinds of fine machining equipment are utilized to process our components.

CNC gantry mill: Used to mill shredder's main shaft.

3E Recycling is combined with a group of innovative, positive and professional personnel. They are willing to bear responsibilities and share honors and disgraces together. In past fifteen years, all our staffs work as a team striving for a positive, efficient, cooperative and creative working atmosphere.

After discussion and exploring towards our products, 3E Recycling's staffs integrate multiple perspectives, deliver times of verifications, so as to prevent unnecessary mistakes, to improve product quality, manufacturing efficiency, and achieve technical upgradation.

3E Recycling laid its emphasis to the quality of its shredders and recycling lines. So a series of quality control methods are carried out, starting from the controlling towards raw materials. Meanwhile, all the equipment delivered to customers are labeled with traceable codes, so as to make its tracing more convenient and easier.

Incoming inspection:

Only qualified raw materials and components could enter our warehouse.

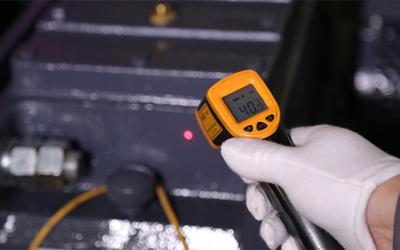

Testing towards machined components:

All the components used in 3E Recycling undergo three-in-one quality inspection system (i.e., workers' self-inspection, mutual inspection and professional inspection). Only qualified ones are able to enter the next manufacturing process.

Flaw detection and testing in riveting place:

The process is carried out to ensure that there is no defect on crucial parts, so as to guarantee the high quality of our components and the safe operation of our products.

Assembly testing:

Another testing will be delivered towards our products before their shipment, so as to ensure the quality of our products.

1. Sophisticated sales team will recommend proper equipment or recovery line solution for you.

2. Invite customers to our factory for site visit, so as to offer our customer a more clear perspective towards our sales team, our designing and our manufacturing procedure.

3. Customer's conformation or amending towards our design towards customized shredder or recycling lines, and then send the design to manufacturing process.

4. After complete the manufacturing in accordance with the design requirements, shredders or recycling lines will be installed, commissioned and checked in our factory under customers' monitoring.

5. 3E Recycling offers om-site installation, commissioning, and personnel training service. Meanwhile, we could also help you to optimize the factory distribution if required, so as to make sure that your staff could learn how to operate the machine or recycling line promptly, and achieve max. manufacturing value.

6. Regular visiting for technical support.

7. 3E Recycling also recommend our customers stock some wearable parts, like cutting tool and screening mesh, thus enables timely replacement and continuous operation of our products. 3E Recycling also owns a large component warehouse, if required, components could be delivered by air transportation, sea transportation, or express to customers.