Heavy Duty Granulator

Firmly welded steel structure is used for the machine shell and supporting rack of the heavy duty granulator, which allows the waste recycling equipment to process and recycle material that is difficult to crush.

This heavy duty pelletizing machine is suitable for crushing sectional material, tubular product, film material, sheet material, large-size solid materials and waste produced during the injection molding process. Our heavy duty granulator is economical, practical, and can be easily operated. Besides, it has a long service life.

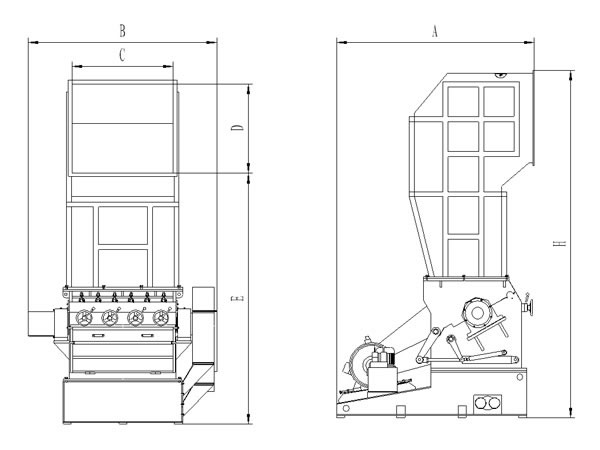

Technical Specifications of Heavy Duty Granulator| Item | Model | Unit | ||||||

| A | (mm) | 2070 | 2027 | 2410 | 2460 | 3000 | 3000 | |

| B | (mm) | 2025 | 2225 | 2320 | 2810 | 2900 | 3300 | |

| C | (mm) | 1000 | 1200 | 1200 | 1600 | 1600 | 2000 | |

| D | (mm) | 700 | 700 | 1000 | 1000 | 1000 | 1000 | |

| E | (mm) | 2200 | 2200 | 3125 | 3245 | 3675 | 3675 | |

| H | (mm) | 2950 | 2950 | 4250 | 4370 | 4765 | 4765 | |

| Rotor Diameter | (mm) | φ520 | φ520 | Ф660 | φ660 | φ800 | φ800 | |

| Main Shaft Speed | (r/min) | 462 | 462 | 462 | 415 | 415 | 415 | |

| Mesh Diameter | (mm) | φ12 | φ12 | φ12 | φ12 | φ12 | φ12 | |

| Rotor Blade Quantity | (PCS) | 5×2 | 5×2 | 5×2 | 5×4 | 7×4 | 7×4 | |

| Stator Blade Quantity | (PCS) | 2×2 | 2×2 | 2×3 | 2×4 | 2×4 | 2×5 | |

| Power | (KW) | 55 | 75 | 90 | 132 | 160 | 200 | |

| Weight | (KG) | 4200 | 5300 | 7650 | 9720 | 11400 | 13600 | |

Notice:

1. The data of screen mesh above is the default specification, and it is available at user's requirement between φ8-φ60.

2. Movable blade number = blade teeth number × number of blade with a tooth in the row; Fixed blade number = row number of blade × blade number in every row

3. The above specifications on our granulating machines are only for reference. Maybe there are some changes that we haven't identified here. Please confirm with our salesman when making orders.

4. The heavy duty granulator can be optionally designed with a third row of fixed blade according to client's requirements.

Related Names

Heavy Duty Granulating Machine