Plastic Granulator

Firmly welded steel structure is used for casing the plastic granulator. The plastic pelletizer can be opened at the connecting position between the material container and the main structure of the machine, making it convenient to clean and remove the blades and maintain the machine.

The structure of blade roll can be changed according to different crushing materials. Optional air conveying collecting units and sound-proofed structures are available for the plastic recycling machine according to your requirements.

As a high performance granulation system, the plastic granulator is suitable for crushing not only plastic products like pipes, sheets, bottles, film, nylon, etc. but also other materials such as rubber.

Technical Specifications of the Plastic Granulator| Item | Model | Unit | ||||||

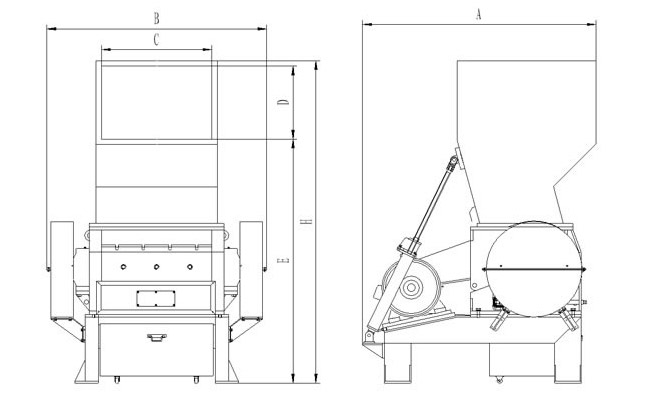

| A | (mm) | 1415 | 1430 | 1580 | 1720 | 1765 | 1765 | |

| B | (mm) | 1030 | 1225 | 1450 | 1630 | 1660 | 1900 | |

| C | (mm) | 400 | 600 | 600 | 800 | 800 | 1000 | |

| D | (mm) | 410 | 410 | 410 | 410 | 550 | 550 | |

| E | (mm) | 1435 | 1440 | 1420 | 1465 | 1845 | 1845 | |

| H | (mm) | 1600 | 1600 | 1860 | 1910 | 2435 | 2435 | |

| Rotor Diameter | (mm) | Ф260 | φ260 | φ320 | φ320 | Ф420 | φ420 | |

| Main Shaft Speed | (r/min) | 500 | 83 | 580 | 580 | 530 | 530 | |

| Mesh Diameter | (mm) | φ8 | φ8 | φ12 | φ12 | φ12 | φ12 | |

| Rotor Blade Quantity | (PCS) | 3×4 | 3×2 | 3×2 | 3×2 | 3×2 | 3×2 | |

| Stator Blade Quantity | (PCS) | 2×2 | 2×2 | 2×2 | 2×2 | 2×2 | 2×2 | |

| Power | (KW) | 11 | 15 | 15 | 22 | 37 | 45 | |

| Weight | (KG) | 660 | 960 | 1470 | 1730 | 2800 | 3230 | |

Related Names

Plastic Granulator | Plastic Crusher