Tyre Recycling Plant

- DebeaderAs one of the components of our waste tyre recycling plant, the debeader form 3E Machinery can effectively retrieve the steel wires around the tire bead to protect the two shaft shredder and its blade from being damaged.

- Tire ShredderThe tire shredder is a kind of double shaft shredder which is able to tear waste tires into pieces with a size of 50×50 mm or above for further treatment. This tire recycling equipment comes with a variety of models.

- Magnetic Separator The magnetic separator is one of the key components of our waste tire recycling plant. It is used for the separation of steel wire from the rubber granules by its powerful magnetic field.

- RasperVarious product configurations. As a kind of tire recycling machine, the rasper is often used after tire shredder to produce smaller rubber granules. The production capacity comes with 400-4000 kg/h.

- Vibrating Screen The vibrating screen is mainly used for the screening of the mixture of rubber and fiber after the rubber material is crushed by the rubber granulator.

- Rubber Granulator The tire recycling machine supports input rubber granules less than 20 mm in diameter, while the output rubber granules are 5-15 mesh. The production capacity of the rubber grinder is 300-1500 kg/h.

- ClassifierDesigned to help process and recycle waste tires, the classifier is used to separate the rubber and fiber from the material after the preliminary shredding.

- Grinding Mill As one of the components of our waste tire recycling system, the grinding mill can grind the rubber particles from 5-15 mesh to 40-80 mesh.

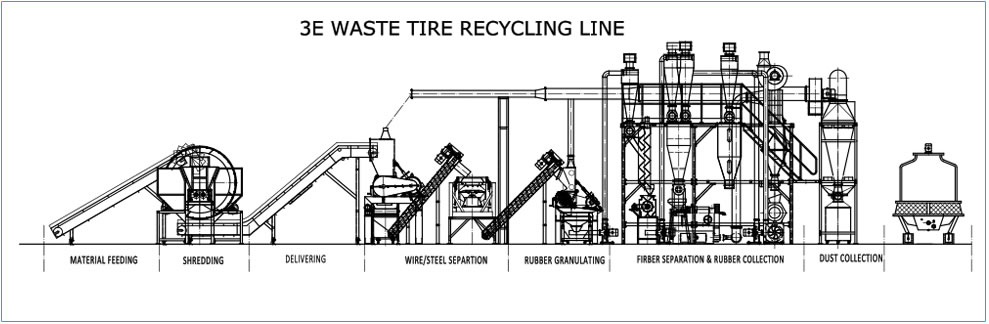

The number of automobile in the world has been increasing, leading to more and more waste tires. These tires, if discarded, will not only pollute the environment, but also mean a waste of potential resource. With the increasing of resources all over the world, discarding waste tires is not economically right any more. Accordingly, 3E Machinery developed the tyre recycling plant. This waste tire recycling line can produce rubber granules of desirable size from waste tires for the construction of asphalt road and plastic track. Thus far, more than 40 sets of tire recycling equipment have been produced for our clients, all of whom gave excellent feedback.

Our line of tyre recycling plants is mainly for waste tires with a diameter of 400-3000 mm. The production capacity reaches 200-10,000 kg/h, while the granules' diameter is 5-100 mesh.

Production LayoutFeatures of the Tyre Recycling Plant

1. PLC control system is adopted for the tyre recycling system. The maintenance and operation are quite simple. A production line with a capacity of 3 ton/hour can be just operated by 4-6 persons at every shift.

2. The rubber, steel wire, nylon fiber can be separated automatically and more efficiently by our tyre recycling line.

3. Our tire recycling machines offer amazing effects in energy efficiency. For example, about 550 KWH of electricity is consumed every hour for producing 3 tons of granules from scrap tires.

4. The blades of the tyre recycling plant have quite long service life. They are also economic and can be maintained for many times.

5. The human-oriented design guaranteed operators' safety and gained the national patents (ZL 2010 2 0602082.4 and ZL 2010 2 0602159.8).

Custom tyre recycling plants are available according to your requirements in terms of production capacity and product size.

Main Components of the Tyre Recycling Plant: (Click the links to see details)

In addition to our tyre recycling plant, we also have waste recycling plant for scrap car, fridge, cable, battery and pipe. If you need to recycle other scrap materials, you can view the corresponding pages on this website.

Related Names

Tire Recycling Machine | Tire Recycling Equipment | Waste Tire Recycling Machine | Used Tire Recycling Machine | Tire Recycling Plant | Rubber Recycling Machine | Tire Recycling Line