PET Bottle Recycling Line

The PET bottle recycling line is used for crushing, cleaning, separating of bottle cap and label, depriving of impurities and glue material, and drying for bottle plates. Then those discarded PET bottles will become reusing PET materials.

We have several different standard PET bottle recycling lines according to different production capacity and requirements for cleaning. Clients can choose the most suitable PET bottle recycling plant to produce high quality material which can be used for selling, drawing filament, producing PET particles or blowing mold bottles. The PET bottle recycling line has a production capacity of 300-2000 kg/h.

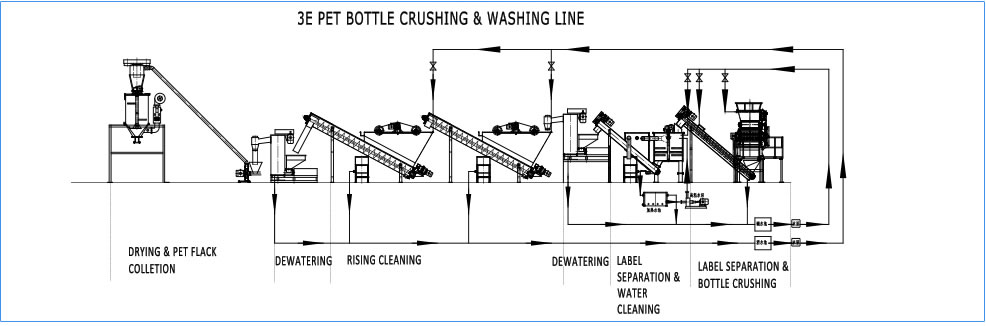

Production LayoutMain Components of the PET Bottle Recycling Line

-

Granulator

Main function: Crushing the plastic bottle into PET flakes -

Sink float tank

Main function: The sink float tank of our PET bottle recycling line is used for cleaning the PET flakes with higher density than water, depriving the substances with a lower density than water such as the labels mixed within the plastic pieces. -

Vertical dryer

Main function: dewatering after cleaning plastic plates , because of using center-hollow shaft and top opening , this plastic recycling machine has a very high drying efficiency(water content percentage≤2.5%). The shaft of this waste processing equipment is also using water-proof design, can keep working steadily for a long time. -

Sink float tank

Main function: cleaning of materials with a lower density than water, and dissection of impurities such as soil. -

Friction washer

Main function: conducting pretreatment such as removing the sand, metal and other impuities, minimizing the potential damage to the recycling machine.

Related Names

PET Bottle Recycling Line | Plastic Bottle Recycling Machine | PET Bottle Recycling Machine | PET Bottle Recycling Plant | PET Bottle Crushing Washing Drying Recycling Line